Earlier this year I was commissioned by the V&A to design a piece of jewellery to go alongside their upcoming exhibition, Plywood: Material of the Modern World. The design was to be based on an exhibit, a plywood aeroplane built in 1912 called the Deperdussin Monocoque. It was a revolutionary plane, breaking the aircraft speed record thanks to the lightweight, strong plywood fuselage. Also, it looks super cute, like a toy!

I thought I'd share my design process for the brooch, now available in the V&A shop, as it was quite a journey, experimenting with a few new materials and techniques.

I started out with some rough sketches of the plane. I always start with a pencil, it helps me work through and make sense of the things floating around my head! I quickly realised that the design was going to be pretty fragile, especially the wings and propeller.

Designing this piece, I really wanted to show off the plywood and make the material a focal point. Instead of simply engraving the design into a flat piece of wood, layering up super thin layers of ply would show depth, strengthen the design and add visual interest. This is an ink drawing of one of the viewpoints we were most happy with. I just love the toy-like shape of the plane!

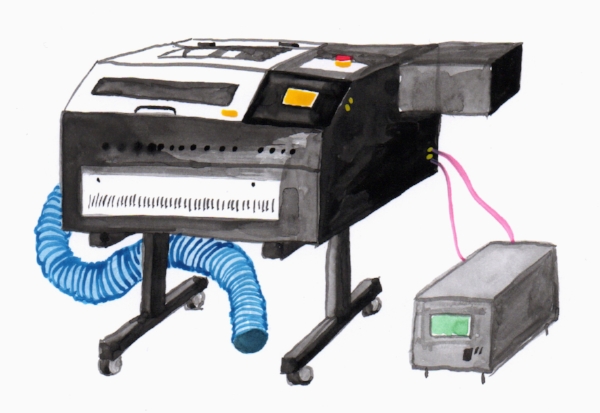

Here's an exploded view of how the plywood layering would work. I create all these vector files for laser cutting on Illustrator. The cloud is made from transparent blue acrylic, and will help support the thinner areas of wood, as well as creating that flying illusion! Now the samples are ready to be laser cut. I had to adjust the design many times during this process, as it was clear that some parts were too small or fragile. I made roughly 8 samples before a final design was realised.

Below are the stacks of different laser cut plywood parts for the final aeroplane design, after being stained and sanded. The smallest pieces are just 2mm wide!

Many hours later, there is a fleet of assembled aeroplane brooches, complete with blue acrylic clouds. The side view shows off the multiple layers of 3.2mm and 0.8mm plywood used. All the plywood I use is sustainably sourced, and is made of either poplar or birch.

I hope this has been an interesting insight into how my work is designed and made! I'm always trying to develop my skills as well as the materials and processes I use to create new, exciting jewellery. This project was challenging, but I'm happy with the final piece, and I'm so excited to see it in the V&A!

The exhibition opens on 15th July, in the Porter Gallery, and it's totally FREE to enter! A must if you're into design, or just a complete nerd about all things wooden like me. The Deperdussin aeroplane brooch will be available to purchase from the V&A store when the exhibition opens.

VISIT THE EXHIBITION

https://www.vam.ac.uk/exhibitions/plywood-material-of-the-modern-world

BUY THE BROOCH

https://www.vam.ac.uk/shop/plywood-plane-brooch-by-kate-rowland-150582.html